AzteQ specialises in the design, supply, installation and support of heat rejection solutions. We do this professionally and successfully for all of our clients.

AzteQ can help ensure the correct equipment is used for the application and provide a cost effective solution to your specification.

Customer hotline 01442 561000

Open Circuit Cooling Towers

AzteQ designs, supplies and where required, installs and maintains the Jacir | GOHL ranges of open circuit, closed circuit and hybrid cooling tower systems.

Jacir | GOHL has been a European market leader for more than half a century, combining its expertise in thermo-dynamics, innovative technologies, premium quality construction materials and state-of-the-art manufacturing processes to offer an extremly wide range of cooling towers for the HVAC, Industrial and power generation markets.

Jacir | GOHL products fulfil and are certified to the “Cooling Technology Institute” (CTI) and “Eurovent” Programmes.

Centrifugal Fan - Models: DT / DT XL / S / ATM / SK / KS

Features include: belt drive, sound attenuation (to 35 dB (A) 10 meters), high level of corrosion protection with easy maintenance, drain points below the lower surface of the pond (complete draining), heat transfer surface PP / PVC and capacities from 20 kW to 5000 kW.

| Features: | Options: |

| Low sound | Whirl Sintering / Z-Steel / X-Steel / 304 SST / 316 SST |

| Low height | Sound attenuation |

| Compact design | Plume abatement (see Hybrid towers) |

| Indoor Installation | |

| Low waterside pressure drop |

Centrifugal EC-Fans - Model: DTC-ecoTec

Innovative German-engineered Cooling Tower in accordance with the latest European Hygiene standards with Eurovent & CTI thermal performance certified. Equipped with EC centrifugal Fans and being extremely silent, the water is distributed in an optimal way over the exchange surface. Entirely designed for easy maintenance thanks to its integrated technical room, the DTC eco Tec is highly energy efficient.

| Features: | Options: |

| 30% energy savings utilising EC direct drive fans, IE4 | Whirl Sintering / 304 SST / 316 SST |

| Low sound level | Sound attenuation |

| Easy Maintenance |

Centrifugal Fan Forced Draught, Low Profile - Model: KRD/WRD

Available with a fully welded wet cell, this range is compact in design, strong and enormously adaptable.

| Features: | Options: |

| Low sound | Stainless Steel, Whirl Sintering* |

| Low height | Extensive accessories |

| High cooling capacity |

*Whirl sintering is a 0,3mm thermoplastic coating for GOHL cooling towers, which delivers operational longevity. It is C5-M certified, the highest corrosion category for coastal and offshore areas.

Axial Fan Forced draught - Model: KH

Features include: belt-drive, low-pressure water supply, frost-free fan, energy saving, high corrosion resistance, easy maintenance, drain points below the lower surface of the pond, the industrial environment is extremely clogging resistance load, heat transfer surface: PVC. Typical capacities from 300 kW to 4000 kW.

| Features: | Options: |

| Low power consumption | Z-Steel / X-Steel / 304 SST / 316 SST |

| Fan motor outside the air stream | Sound attenuation |

| Easy motor and fan maintenance |

Axial Induced draught - Models: VAP / TEC / RMP

New generation axial fans with direct motor-fan propulsion, energy-saving, FRP self-supporting housing, complete corrosion resistance, easy maintenance, UV-resistant drain points below the lower surface of the pond, fast on-site installation, industrial environment resistant heat transfer surface fouling. Typical capacities form 250 kW to 10,000 kW.

| Features: | Options: |

| Low power consumption | GRP / Z-Steel / X-Steel / 304 SST / 316 SST |

| Small footprint | Sound attenuation |

| Easy maintenance |

X-Stream

Centrifugal & Axial fan - Models: RC / RH / RBH

For heavy duty waters within such industries as Food & dairy, Steel Production, Automotive & Sugar Refining. The designs incorporate features such as Vertical pitch: 200 mm to 500 mm, Horizontal pitch: 32 mm or 64 mm & Water temp max 100 °C.

- Designed for extreme conditions of water and air quality

- Very high resistance to clogging

- Very high mechanical resistance: 30 Kg/m2

- Highly Simplified access for cleaning and maintenance

- For water up to 400ppm suspended solids

X-Tract

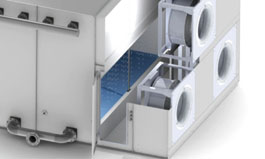

X-Tract System has been specially designed to simplify installation and maintenance operations. In a single lift, exchange surface, water distribution and drift eliminators are integrally removed allowing then a complete cleaning of the internals and of the casing on the ground.

- Complete cleaning of the internals in safe conditions and without any dismantling.

- Low maintenance duration, leading to the spacing of short process stops

- Total accessibility of the internals and tower structure for ease of maintenance

- Longer lifetime

- Guaranteed and stable cooling capacity

AzteQ can supply and where required, install a range of water treatment & Legionella control solutions, associated with the safe operation of Cooling Towers and Hybrid Coolers.